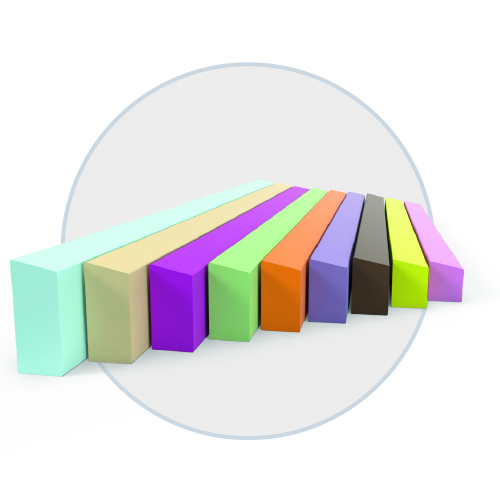

The elastomers were especially developed for diecutting technology, so that the product properties exactly meet the cutting process requirements and deliver optimum results even for the most demanding orders and complex layouts.

Cutting dies with the CITO Quality Label

For optimum performance, efficient processes and outstanding quality

The challenges and standards for packaging are increasing – be on the winners’ side and use tools that are worth their price in terms of quality and performance.

Because good quality is worth it. It pays to invest in a good tool instead of paying for the perceived saving with reduced production performance, high process costs and unnecessary waste of resources.

We created the CITO Ejection Material quality label so that converters know which materials have been used on the cutting die. This quality symbol on the tool means that high-quality elastomers have been applied.

CITO Ejection Material

With these properties you produce quality

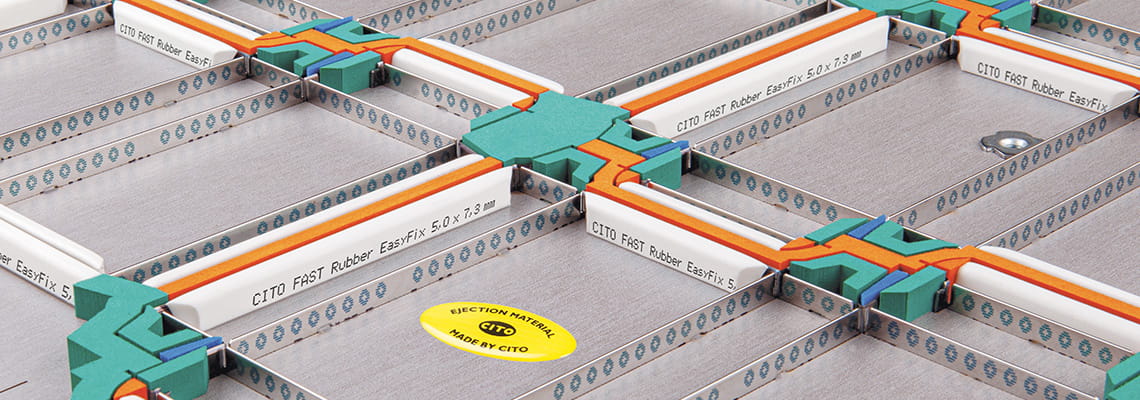

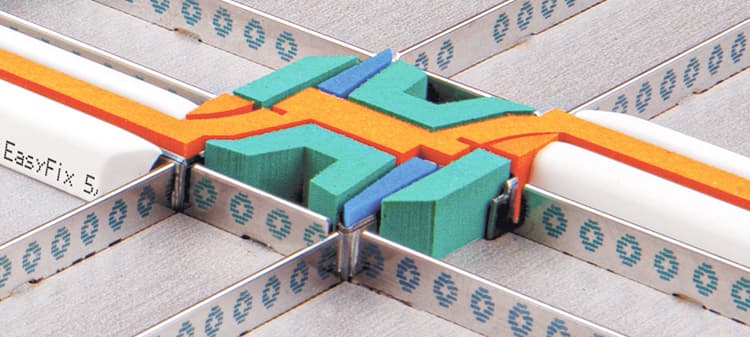

CITO EasyFix

The ejection materials are equipped with the original CITO EasyFix technology. This unique adhesive technology enables convincingly quick, easy and exact attachment of the elastomers. The cutting rules do not stick. The makeready is significantly faster. The cutting die remains intact.

ISEGA certification

The products are now almost all ISEGA certified and can therefore be used safely for the production of food packaging.

Your advantages:

- Optimum machine performance and maximum output

- Efficient and safe processes that use resources carefully

- Fast and easy makeready

- Standardised and constant tool quality

- Cutting dies with high output rates and long durability

- Enormous potential savings in production costs

For optimum value for money, outstanding results – simply more profit. Opt for the original CITO Quality Label for future orders of cutting dies.

Quality cutting dies

Examples of uncompromising quality

The function of the ejection material used is described as well as the specific rubber lining and production advantage explained.

Our recommendations for the conversion of solid board and corrugated board – for your daily requirements and orders.

Solid board

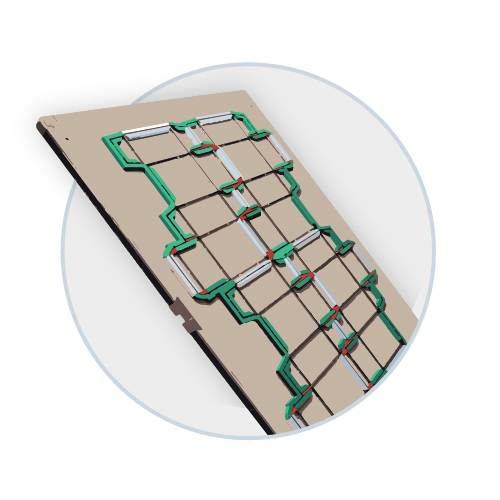

The high performance CITO Polytop material and the CITO MASTER Rubber premium-C profile have been applied on this cutting die. Both products are characterised, in particular, by the fact that they can produce consistently excellent quality, even at maximum machine speeds and for the largest orders. The tools have a long service life and are therefore also the most reliable and best choice for repeat orders. CITO Polytop and CITO MASTER Rubber are optimally suitable for high performance dies.

CITO Polytop 40 ORANGE

The ejection profile keeps the sheet flat on the cutting plate during the cutting process. Otherwise the individual cut material can jam between the cutting rules and is lifted again, which would cause sheet and blank cracks. The flat position of the sheet enables constant and fault-free machine running. With CITO Polytop the sheet remains intact and enables uniform sheet transport – even at full machine speed. CITO Polytop maintains its uniform excellent performance, also for large orders and maximum speeds. Even high temperatures do not affect the material’s ejection force.

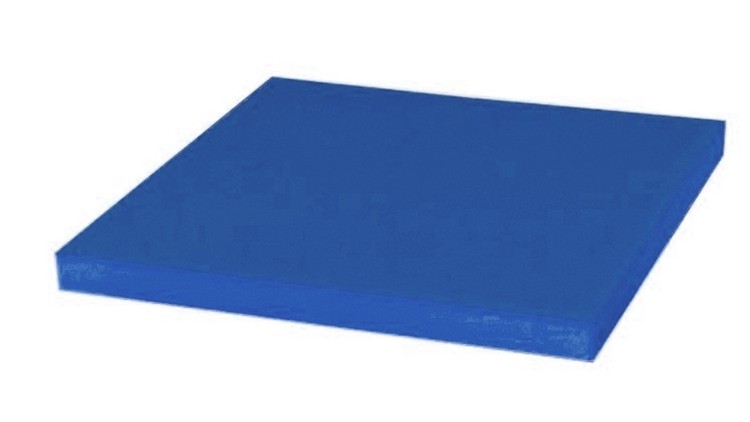

CITO Polytop 50 DARK BLUE

The high performance material is used here for small distances between the cutting rules. As smaller pieces of waste exert more resistance and stress, and jam between the cutting rules faster, CITO Polytop 50 DARK BLUE operates with a higher ejection force in this area and thus prevents jamming. The waste is therefore reliably kept in the sheet until the stripping process. As with the other CITO Polytop products, the excellent material properties are convincing, even with the largest runs and maximum machine speeds.

CITO MASTER Rubber

The premium profile is applied here on cutting rules with nicks. The material properties of the profile and its special C-shape compensate for tensile forces formed, among other things, by the creasing process. Fewer and smaller nicks can be set, especially in the machine running direction, without having a negative effect on the machine speed. This also has a positive effect on the subsequent blanking process.

Solid board

The standard CITOject F material and the CITO FAST Rubber C-profile were used for this cutting die. Both products are characterised by the fact that constant quality is produced. The tool life is increased by the reliability of the ejection material. CITOject F and CITO FAST Rubber are ideally suitable for standard applications.

CITOject F 35 GREEN /

CITOject F 45 ORANGE

The ejection material keeps the sheet flat on the cutting plate during the cutting process. Otherwise the individual cut material can jam between the cutting rules and is therefore lifted again. The flat position prevents sheet and blank cracks. The diecutter runs smoothly and reliably without standstill. The CITOject F material keeps the sheet intact and therefore safeguards uniform sheet transport.

CITOject F 55 BLUE

The elastomer is used for narrow distances between the cutting rules. As smaller pieces of waste exert more resistance and stress, and jam between the cutting rules more quickly, the higher ejection force of the profile in this area prevents jamming. The result: The waste area is kept reliably in the sheet until the stripping process.

Corrugated board

CITO Polytop was specifically utilized for this corrugated board tool. The high performance ejection material was deliberately chosen here for the rubber lining – even for smaller print runs and lower mileage.

The elastomer not only performs convincingly at high machine speeds and with large print runs, but also proves its worth excellently in the processing of critical materials and complex orders. Thanks to the fine material grading, dents in the substrate are avoided and the set-up times are reduced.

CITO Polytop 20 YELLOW

The high performance material keeps the sheet flat on the cutting plate during the cutting process. Otherwise the individual cut material can jam between the cutting rules and is lifted again. This would lead to sheet and blank breaks and have a negative effect on smooth machine running. With CITO Polytop the sheet remains intact, which ensures uniform sheet transport. The flute is not deformed.

CITO Polytop 40 ORANGE

The ejection material is used here in the narrow distances between the cutting rules. As smaller pieces of waste exert more resistance and stress, and jam between the cutting rules more quickly, the CITO Polytop 40 DARK ORANGE operates here with higher ejection force and thus jamming is prevented. The waste is therefore reliably kept in the sheet until the stripping process. The ejection forces on the nicks are balanced so that the nicks do not break.

Digital service solutions

Available online at anytime and anywhere

In addition to quality products, reliable service and expert advice, you also receive digital technical support, so that you can select and use CITO Ejection Material optimally and efficiently.

CITO Ejection Performance Guide

The CITO Ejection Performance Guide has been developed by the CITO GROUP experts. With the online tool you can calculate the suitable ejection material simply and quickly.

How it works:

- Enter the key data of the respective order

- Direct individual material recommendation

- PDF guide for extensive and detailed information

With the CITO Ejection Performance Guide, you always receive precisely the right recommendation for all your specific requirements and orders – simply online with a click!

CITO Online Seminars

The online seminars impart sound and up-to-date knowledge for the conversion of solid and corrugated board. Benefit from our experience in your daily application.

- Knowledge and technology – application orientated, practical, extensive

- Detailed and understandable explanations – with videos and animations

- Know-how 24/7 – available online at anytime and anywhere

Register now – easily and quickly. After registration, you will receive free access to our exclusive online seminars.

CITO Ejection Material for quality cutting dies

Performance and output

Trust, reliability and safety

Know-how and experience

First class product properties

Cost and resource efficiency

Contact us!

Apply for the CITO Quality Label

For further information or to apply for the CITO Quality Label, please contact Stefan Großkopf or Michael Schuster.