HS CITO cutting rules offer you excellent value for money. All cutting rules in the HS CITO series are equipped with a hardened edge for premium cutting and longer life expectancy. HS CITO cutting rules have outstanding bendability; due to the deep decarburization of the body there are no cracks during the bending process.

HS CITO SuperBend

The well-balanced hardening technology can cope with even the smallest bending angle. The hardened edges allow excellent service life.

Drawn blade, standard

Standard version; features excellent bending characteristics and a precise line height

Ground blade GR

A sharper blade that produces clean and precise cut edges; suitable for thicker or tougher materials, e.g. plastics, rubber, laminates and coated materials; creates less cutting dust, lower friction reduces cutting pressure, excellent bending characteristics, rounded transition from blade to body.

| HS CITO SuperBend | |

|---|---|

| Thickness | 2 pt / 3 pt / 4 pt |

| Body hardness | 350 HV |

| Edge hardness | 630 HV |

| Height | 22.30 – 50.00 mm |

| Type of cutting bevels | CB / CFB |

| Finish of cutting bevel | drawn / ground |

| Cutting angle | 52° / 42° |

HS CITO SwordCut

Precision-ground blade

The precision-ground blade and maximum dimensional accuracy reduce the cutting pressure, prevent the formation of angel hairs and cutting dust.

| HS CITO SwordCut | ||

|---|---|---|

| Thickness | 2 Pt. | 3 Pt. |

| Body hardness | 380 HV | 350 HV |

| Edge hardness | 630 HV | |

| Height | 23.80 mm | |

| Type of cutting bevel | CB / CFB | |

| Finish of cutting bevel | precision ground | |

| Cutting angle | 52° / 42° | |

Forms of delivery and packaging units

HS CITO cutting rules are available in coils.

Winding direction: Clockwise / Anti-Clockwise

| Thickness | Contents coils |

|---|---|

| 2 pt | 100 m |

| 3 pt | 50 m |

| 4 pt | 50 m |

Note: Our rule geometrics and standards comply with the standards of the European Diemakers Association (EDA).

Types of cutting bevels

CB

Center Bevel

The most widely used cutting bevel for all common cardboard materials

CFB

Center Facette Bevel

= Long Center Bevel

Applicable for hard and thicker materials, e. g. corrugated board, plastics, glass-fibre reinforced laminates, leather, cork, rubber, puzzles etc.

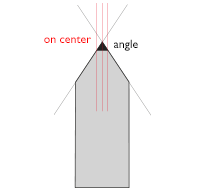

Types of cutting angle

HS CITO Cutting Rules are availablein the cutting angles 42° and 52° +2°/-0°.

Download

Safety Data Sheet HS CITO

english

Stand: 2024-07-26T19:01:13+02:00

Product leaflet

Technical data sheets