Offset creasing matrices are ideally suitable for top quality creases. They can be supplied as Standard or Off-Center versions. Various dimensions are available for different printing substrates.

RSP Offset Creasing Matrix is also perfect for use on rotary diecutters.

Standard ORS

| Dimensions (H × W × L) | Contents | Unit | Order no. |

|---|---|---|---|

| 0.2 × 0.8 × 700 mm | 30 pcs. | 1 packet | ARE02001 |

| 0.2 × 1.0 × 700 mm | 30 pcs. | 1 packet | ARE02002 |

| 0.2 × 1.2 × 700 mm | 30 pcs. | 1 packet | ARE02003 |

| 0.2 × 1.3 × 700 mm | 30 pcs. | 1 packet | ARE02004 |

| 0.3 × 0.7 × 700 mm | 30 pcs. | 1 packet | ARE03002 |

| 0.3 × 0.8 × 700 mm | 30 pcs. | 1 packet | ARE03003 |

| 0.3 × 1.0 × 700 mm | 30 pcs. | 1 packet | ARE03004 |

| 0.3 × 1.2 × 700 mm | 30 pcs. | 1 packet | ARE03006 |

| 0.3 × 1.3 × 700 mm | 30 pcs. | 1 packet | ARE03007 |

| 0,4 × 1.3 × 700 mm | 30 pcs. | 1 packet | ARE04007 |

| 0,5 × 1.3 × 700 mm | 30 pcs. | 1 packet | ARE05007 |

Further sizes available upon demand.

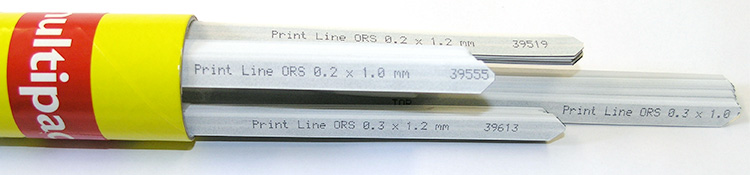

RSP Multipack ORS

| Dimensions (H × W × L) | Contents | Unit | Order no. |

|---|---|---|---|

| 0.2 × 1.0 × 700 mm 0.2 × 1.2 × 700 mm 0.3 × 1.0 × 700 mm 0.3 × 1.2 × 700 mm | 10 pcs. 10 pcs. 10 pcs. 10 pcs. | 1 packet | ARU02001 |

Off-Center OCC

| Dimensions (H × W × L) | Contents | Unit | Order no. |

|---|---|---|---|

| 0.3 × 1.0 × 700 mm | 30 pcs. | 1 tube | ARD03002 |

| 0.3 × 1.1 × 700 mm | 30 pcs. | 1 tube | ARE03005 |

| 0.3 × 1.2 × 700 mm | 30 pcs. | 1 tube | ARD03003 |

| 0.3 × 1.3 × 700 mm | 30 pcs. | 1 tube | ARD03004 |

Further sizes available upon demand

Technical info

RSP Inline Finishing offers you several options for integrating creasing into sheet fed printing. Creasing of printing substrates at the same time with perforations or impressions is also possible. Regardless of whether you call it creasing, grooving or pre-folding: it is always important to achieve adequate ply separation of the board or paper to prevent crease breaking during folding.

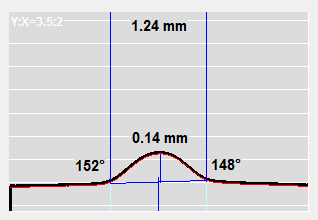

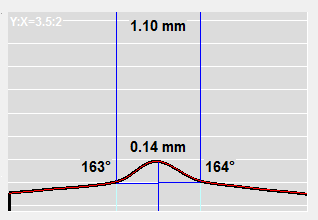

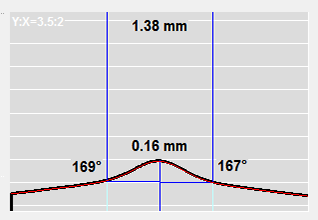

We have compared the creasing of our different creasing matrices using the CITO CREASY measuring device for you. The CITO CREASY checks the geometry and characteristics of the creasing and its dimensions.

In the comparison of the 3 options it becomes clear that an optically perfect creasing fold is achieved with the ORS creasing matrix and the characteristics are the strongest. The creasing with the creasing plate and creasing rubber meet the requirements for optimum further processing.

The creasing plate and creasing rubber are particularly suitable for double and multiple creasing, or for more complex forms.

Selection of RSP Creasing Matrix

| Thickness of material | With lines | With flexible dies |

|---|---|---|

| 0.10 mm | 0.3 × 0.7 mm | 0.2 × 0.8 mm |

| 0.15 mm | 0.3 × 0.8 mm | 0.2 × 0.8 mm |

| 0.20 mm | 0.3 × 1.0 mm | 0.2 × 1.0 mm |

| 0.25 mm | 0.3 × 1.0 mm | 0.2 × 1.0 mm |

| 0.30 mm | 0.3 × 1.2 mm | 0.2 × 1.2 mm |

| 0.35 mm – 0.50 mm | 0.3 × 1.3 mm | - |

Note:

The values mentioned above are guide numbers and are therefore not binding.

The following factors have an important influence on the correct creasing matrix:

- Pressure supply

- Hardness of material to be imprinted

- Humidity of material to be imprinted

- Makeready of the grid sheet

Media

Download

Stand: 2024-09-19T19:01:15+02:00