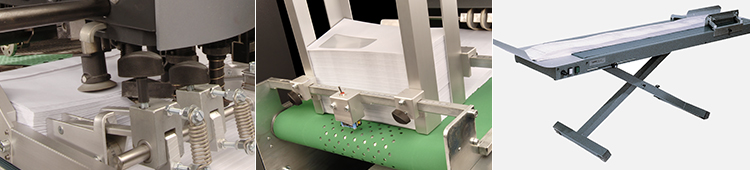

SUPERFEEDER – Envelope feeder for offset printing

Maximum production rate without stopping the machine

With the SUPERFEEDER, you achieve a professional result with every printed envelope! The envelope feeder was especially developed for the particular requirements when processing envelopes; it impresses with its sturdy construction as well as the easy and fast set-up on all small-format printing presses. Its robust design in particular makes the envelope feeder a worthwhile investment.

A calculation example illustrates this: With a throughput of approx. 200 million envelopes, the price for one envelope is only € 0.00015 or, in other words, more than 6,500 envelopes can be stacked quickly and easily for 1 cent.

With the SUPERFEEDER, all standard envelope sizes can be processed at maximum machine speed, without having to stop the printing machine in between times for manual stacking.

The envelope feeder optimises your printing workflow and ensures constant and reliable feeding of envelopes into your offset printing machine. By automating the feeding of your envelopes, you increase the production efficiency of your company considerably.

Your advantages:

- Fast and easy setting up

- Less start-up waste

- Designed for all standard envelope sizes and types

- Optimised workflow for constant and reliable performance

- Reduced time, personnel and costs required

- Maximum production rate

- No stopping of the printing machine for manual stacking

- Higher printing quality due to constant machine running

- Long service life for fast payback

Technical data

- Length 1,210 mm

- Width 500 mm

- Table height 880 – 1,150 mm

- Inclination 0 – 8°

- Weight 112 kg

- Electrical power supply 230 V 50 Hz

- Max. speed 15,000 items/hour

- Smallest format 92 × 92 mm

- Largest format 365 × 365 mm

- C6 lengthways and crosswise to B4 lengthways and crosswise

- Minimum width of printing press 28 cm

| Description | Unit | Order no. |

|---|---|---|

| SUPERFEEDER envelope feeder | 1 pc. | BWA00001 |

| Additional front plate for single-sheet printing press with photoelectric cell | 1 pc. | BWA00002 |

| Delivery belt for SUPERFEEDER: 1.1 m | 1 pc. | BWA00003 |

| Extra long delivery belt for SUPERFEEDER: 1.6 m | 1 pc. | BWA00004 |

SUPERFEEDER – Envelope feeder for offset printing

Positive feedback from users

Numerous printers’ shops in Germany are already benefiting from using the SUPERFEEDER.

We would give 10 out of 10 points!

Company: Druckerei Pircher GmbH

Company: Druckerei Pircher GmbH

Created by: Hans Pircher, Senior Manager and Hannes Pircher, Managing Director

We are pleased when our printers are doing really well. We attach a great deal of importance to state-of-the-art equipment with excellent running properties.

Since we have had the SUPERFEEDER envelope feeder, the machine runs permanently without problems. We are very satisfied, the envelopes run faultlessly at maximum speed through the printing machine, so that our operators have their hands full to remove the envelopes at the front and insert them again at the back.

The SUPERFEEDER runs perfectly and it is one of our best investments. We would like to thank CITO for the swift processing of the delivery and the sensational support.

We would give 10 out of 10 points.

Fast and easy setup – production at maximum speed!

Company: Schöttner Offsetdruck GmbH

Company: Schöttner Offsetdruck GmbH

Created by: Hans Schöttner, Management

How did we arrive at the SUPERFEEDER? As our previous feeder no longer produced the necessary performance, we looked around for a new envelope feeder at short notice. While looking for a suitable model we came across the SUPERFEEDER.

The advantages of the envelope feeder convinced us and we opted to buy it. Following comprehensive and professional training by the CITO application engineers, not only the C4 envelopes run at maximum speed, but we can also produce special format envelopes significantly better with the new feeder. The fast and easy setup and production and maximum speed characterise the robust device.

SUPERFEEDER: This envelope feeder has consistently proven its reliability throughout its entire period of operation.

Company: DATEV eG, Nuremberg

Created by: Harald Benker, Team Management, Printing Service

We have been using the SUPERFEEDER envelope feeder in our offset production facility since 2010. Right from the start, we have been impressed with its short setup time. This envelope feeder has consistently proven its reliability throughout its entire period of operation.