Details

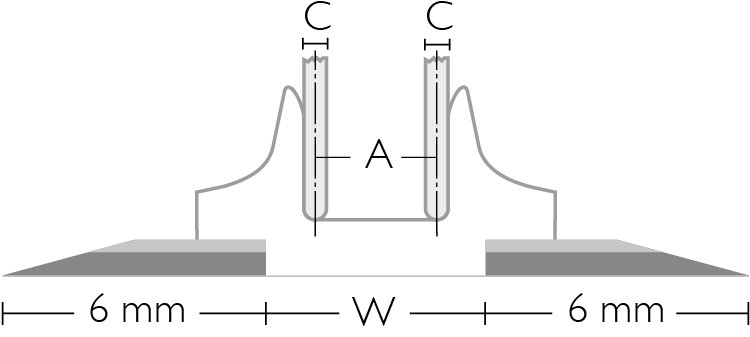

Contents of box 50 × 70 cm = 35 m; Further sizes regarding creasing channel depth, width and locator available upon demand. A = creasing rule distance center/center | |||

| H × W/A mm | H × W/A mm | H × W/A mm | H × W/A mm |

|---|---|---|---|

| 0.6 × 5.0/3 | 0.7 × 5.0/3 | 0.8 × 5.0/3 | 1.0 × 5.0/3 |

| 0.6 × 6.0/4 | 0.7 × 6.0/4 | 0.8 × 6.0/4 | 1.0 × 6.0/4 |

| 0.6 × 7.0/5 | 0.7 × 7.0/5 | 0.8 × 7.0/5 | 1.0 × 7.0/5 |

| 0.6 × 8.0/5 | 0.7 × 8.0/5 | 0.8 × 8.0/5 | 1.0 × 8.0/5 |

| 0.7 × 9.0/6.5 | 0.8 × 9.0/6.5 | 1.0 × 9.0/6.5 | |

Technical Information

Customer Testimonials

Perfect result with CITO ULTIMATE and competent expert advice

Company: Gugler GmbH

Company: Gugler GmbH

Created by: Markus Ackermann, Team leader print and finishing

The customer's requirement was an extremely brittle 600 g grey board that had to be converted with several clean creases.

Thanks to intensive advice from the CITO experts, a perfect result was achieved with the CITO ULTIMATE creasing matrix (1.0 × 3.5 mm).

CITO ULTIMATE – creases perfectly even where others give up!

Company: STEFFEN MEDIA GmbH

Company: STEFFEN MEDIA GmbH

Created by: Sven Steffen, Managing Director

By using CITO ULTIMATE, cracking of the crease was prevented. We now use ULTIMATE CS 0.4 × 1.0 mm and ULTIMATE RS 0.4 × 1.0 mm and are completely satisfied with the creasing quality.

CITO ULTIMATE creases where other creasing matrices give up.

CITO ULTIMATE CS | CITO ULTIMATE RS

CITO ULTIMATE – absolutely residue-free detachment and high machine speeds

Company: WERNER KENKEL Spółka z o.o.

Company: WERNER KENKEL Spółka z o.o.

Created by: Zbigniew Majer, Production Manager

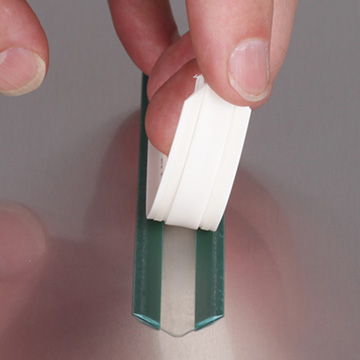

Unlike other creasing matrices, the CITO creasing matrix has never left adhesive residues on the cutting plate after production has finished. This is very practical, as the CITO creasing matrix can be removed very quickly and effectively; removing adhesive residues, which is necessary when other matrices on the market are used, is very time-consuming and tedious. On removing the creasing matrix, the base does not detach from the adhesive film, which effectively holds the creasing system on the cutting plate.

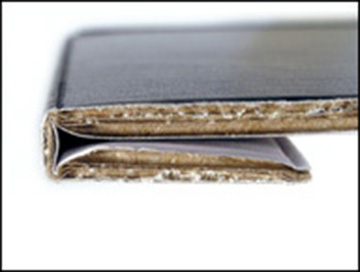

In the CITO ULTIMATE series, the shape of the creasing system is specially designed so that the sheet runs smoothly over the plate, which leads to very good sheet transfer and enables us to achieve higher machine speeds. Thanks to the chamfered outer edges, the ULTIMATE creasing system does also not require additional reworking, which in turn reduces set-up time.

In addition, the flexible upper layer prevents the building of marks along the edges of the creasing system. The flexible coating and shape of CITO ULTIMATE definitely help to reduce the number of material breaks that occur during cutting.

CITO ULTIMATE: no white broken edges, no reworking necessary

Company: THIMM Display GmbH, Wörrstadt

Created by: Nico Prybylski, Team leader diecutting

The die-cutting team at THIMM Display have been working with the new CITO ULTIMATE creasing matrix for some time now. We are pleased by the ever increasing range of sizes that are available. The advantages are obvious: no white broken edges when folding over lugs or body edges of trays, counter displays as well as bases during gluing, etc. This saves makeready time because the creasing matrices do not, or only very rarely, have to be reworked.

CITO ULTIMATE: It has a decent advanced mileage compared to CITO PRO

Company: Intermart Exports (Pvt) Ltd.

Company: Intermart Exports (Pvt) Ltd.

Created by: Amila Paranamanage, Manager Production

I would like to mention that we are very happy about your new product CITO ULTIMATE due to few reasons as follows:

- It has a decent advanced mileage compared to CITO PRO.

- We feel that dust is reduced during creasing.

- Perfect bond with the jacket and no tendency to remove while in production.

- Same unique creasing quality maintaining throughout the run.

- And also we can run at a high speed because of self-pushing feature pushing the sheet in a rhythm while in operation.

So, we hope to continue with this product with thanks.

Download

Stand: 2024-04-26T19:01:09+02:00

Product leaflet

ISEGA Certificate

ISEGA Certificate